Welcome Mid-West Mechanical Parts !

MWMECH

MWE-1901

yes

SKH51

| Availability: | |

|---|---|

| Quantity: | |

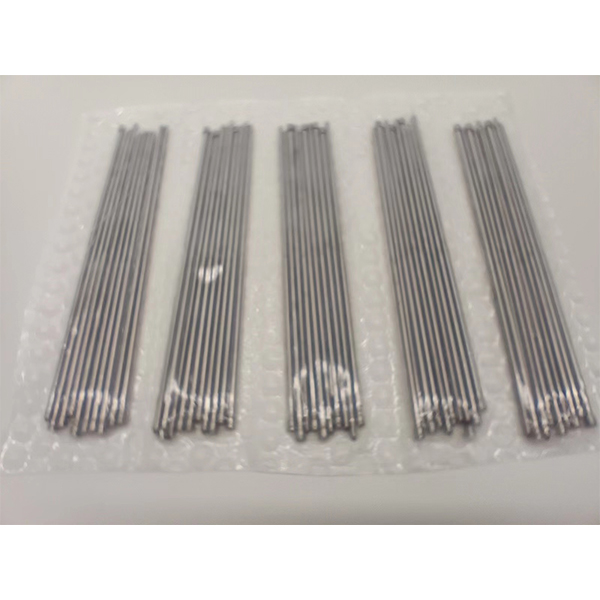

In the stamping die, the ejector pins are installed in to make the plastic deformation and separation of metal or non-metal materials, and form final parts.

In the plastic moulds and die casting moulds, they're mainly used for shaping up holes of parts, or separating the finished parts from the fixed die plate.

According to the shape, the ejector pin can be typed into circular, elliptical, square and so on.

These pictures are our customized products. It shows our supply ability. Due to the Intellectual Property, it's only for reference.

The usual use for separating the final products from the fixed die plate of the plastic mode, the stamping die, and the die casting mould.

To break through the long hole.

As a slide pin inserting in the plastic mode for positioning.

Die casting mold insert.

Shaping up holes of parts In the plastic moulds and die casting moulds.

To make the plastic deformation In the stamping die.

Material: HSS, SKH51, SKD11, SKD61, ASP23, SUJ2....

Hardness: 50-63 HRC

Tolerance scope: +/-0.002mm - +/-0.005mm

Application: the stamping die, the plastic moulds, the die casting moulds

You need to provide clear drawings and requirements so as to for our engineers understand thoroughly. We can also supply precision mechanical parts as below:

Non-Standard Mechanical Parts,

Assemble Line Punch,

Assemble Line Head Punch,

Assemble Line Connecting -Adapter Parts,

Assemble Line Mounting Plate Components,

Assemble Line Metal Gripper,

Assemble Line Guide Sleeves,

Assemble Line Orientation Inserts,

Assemble Line Flange Connector parts,

Assemble Line Device,

Orientation Parts for Assemble Line,

Measurement Parts for Assemble Line,

Inspection Parts,

Non- Standard Metal Dividing Cutters Assemble Line Tooling…

Good consistency, stable quality, precision tolerances +/-0.002mm to +/-0.005mm.

Almost zero repair rate, and defective products all replacement or repair for free due to our fault within 1 year warranty period.

Reliable substitute of German (HASCO) or Japan (MISUMI) similar mode parts with perfect quality whereas with very reasonable price.

ISO quality assurance system.

Fast after-sale respond.

Inner: bubble bag, PE bag or plastic seal with anticorrosive oil plus outer carton box, or other safe package.

|  |

The main surface treatment methods of die accessories are: electroplating, spraying, polishing, anodizing, blackening, etc.

The function is to improve the appearance, the corrosion resistance and wear resistance of the mold parts. Each has its own unique use environment and condition as below:

Steel Material Electroplating

Electroplating-Electroplating is a method of treating the surface of die accessories with a layer of metal film. Different metals, such as chromium, zinc, or nickel, are used as coatings in different utility environments.

Usage: It is used for parts with low dimensional accuracy requirements. Because the thickness uniformity of electroplating is not easy to control, the accessary processing is required to ensure the accuracy when the dimensional accuracy is high.

Steel Material Spraying

Spraying refers to the treatment method of spraying a layer of coating on the surface of mold accessories.

Usage: It can be used as the final surface treatment for parts requiring high dimensional precision and high wear resistance.

Steel Material Polishing

Polishing refers to treat the surface into a smooth, flat, burr free state.

Usage: To improve the appearance, the micro roughness and wear resistance of the die parts.

Common Steel Blackening

Blackening refers to the method of treating the surface of mold accessories into a layer of black oxide film.

Usage: Ordinary steel as a kind of mold parts material, if it’s performance needs and corrosion resistance requirements are not high, blackening treatment can be cost saving.

Aluminum Anodizing

Anodizing- Anodizing refers to treat the surface of die parts into a layer of oxide film.

Usage: Because of its low hardness, usually used as an auxiliary mold accessories.

You may choose surface treatment according to your needs. Below are some usual methods we use.

FAQ

Q: What service can you do?

A: OEM/ODM. Free samples available after price confirmed, but you need to share the sample freight. We produce the parts per customers'drawing or sample. Concerning the protection of customers'intellectual property, we don't sell our customers'same product to the third party.

Q: What data should the customer provide for a precise quotation?

A: The drawings or samples, quantity, tolerance, standard, material, surface finish, other special requirements, etc.

Q: What're your delivery methods?

A: DHL, EMS, UPS, land transport or sea freight available.

Q: How do you assure the quality control?

A: Full inspection with test report and material composition certificate for each order and 1-year after-sale service for free repair or replacement for deficit products. Almost zero repair rate and defective products all replacement or repair for free.

Q: How long is your lead time?

A: 10-30days up to the quantity.

Q: what surface treatments can you deal with?

A: Titanium nitride (TiN), TiCN, titanium plating, blackening, carburize, zinc plating, zinc coating, galvanization, chrome plate, etc.

Q: what's your payment term?

A: T/T, L/C, western Union, PayPal, etc.

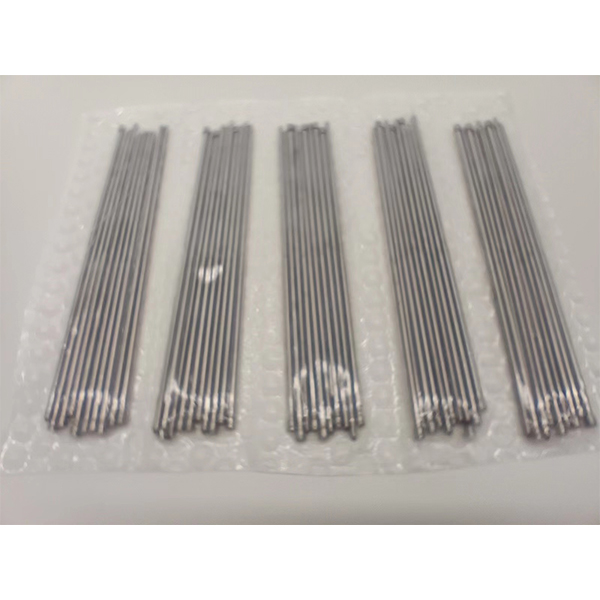

In the stamping die, the ejector pins are installed in to make the plastic deformation and separation of metal or non-metal materials, and form final parts.

In the plastic moulds and die casting moulds, they're mainly used for shaping up holes of parts, or separating the finished parts from the fixed die plate.

According to the shape, the ejector pin can be typed into circular, elliptical, square and so on.

These pictures are our customized products. It shows our supply ability. Due to the Intellectual Property, it's only for reference.

The usual use for separating the final products from the fixed die plate of the plastic mode, the stamping die, and the die casting mould.

To break through the long hole.

As a slide pin inserting in the plastic mode for positioning.

Die casting mold insert.

Shaping up holes of parts In the plastic moulds and die casting moulds.

To make the plastic deformation In the stamping die.

Material: HSS, SKH51, SKD11, SKD61, ASP23, SUJ2....

Hardness: 50-63 HRC

Tolerance scope: +/-0.002mm - +/-0.005mm

Application: the stamping die, the plastic moulds, the die casting moulds

You need to provide clear drawings and requirements so as to for our engineers understand thoroughly. We can also supply precision mechanical parts as below:

Non-Standard Mechanical Parts,

Assemble Line Punch,

Assemble Line Head Punch,

Assemble Line Connecting -Adapter Parts,

Assemble Line Mounting Plate Components,

Assemble Line Metal Gripper,

Assemble Line Guide Sleeves,

Assemble Line Orientation Inserts,

Assemble Line Flange Connector parts,

Assemble Line Device,

Orientation Parts for Assemble Line,

Measurement Parts for Assemble Line,

Inspection Parts,

Non- Standard Metal Dividing Cutters Assemble Line Tooling…

Good consistency, stable quality, precision tolerances +/-0.002mm to +/-0.005mm.

Almost zero repair rate, and defective products all replacement or repair for free due to our fault within 1 year warranty period.

Reliable substitute of German (HASCO) or Japan (MISUMI) similar mode parts with perfect quality whereas with very reasonable price.

ISO quality assurance system.

Fast after-sale respond.

Inner: bubble bag, PE bag or plastic seal with anticorrosive oil plus outer carton box, or other safe package.

|  |

The main surface treatment methods of die accessories are: electroplating, spraying, polishing, anodizing, blackening, etc.

The function is to improve the appearance, the corrosion resistance and wear resistance of the mold parts. Each has its own unique use environment and condition as below:

Steel Material Electroplating

Electroplating-Electroplating is a method of treating the surface of die accessories with a layer of metal film. Different metals, such as chromium, zinc, or nickel, are used as coatings in different utility environments.

Usage: It is used for parts with low dimensional accuracy requirements. Because the thickness uniformity of electroplating is not easy to control, the accessary processing is required to ensure the accuracy when the dimensional accuracy is high.

Steel Material Spraying

Spraying refers to the treatment method of spraying a layer of coating on the surface of mold accessories.

Usage: It can be used as the final surface treatment for parts requiring high dimensional precision and high wear resistance.

Steel Material Polishing

Polishing refers to treat the surface into a smooth, flat, burr free state.

Usage: To improve the appearance, the micro roughness and wear resistance of the die parts.

Common Steel Blackening

Blackening refers to the method of treating the surface of mold accessories into a layer of black oxide film.

Usage: Ordinary steel as a kind of mold parts material, if it’s performance needs and corrosion resistance requirements are not high, blackening treatment can be cost saving.

Aluminum Anodizing

Anodizing- Anodizing refers to treat the surface of die parts into a layer of oxide film.

Usage: Because of its low hardness, usually used as an auxiliary mold accessories.

You may choose surface treatment according to your needs. Below are some usual methods we use.

FAQ

Q: What service can you do?

A: OEM/ODM. Free samples available after price confirmed, but you need to share the sample freight. We produce the parts per customers'drawing or sample. Concerning the protection of customers'intellectual property, we don't sell our customers'same product to the third party.

Q: What data should the customer provide for a precise quotation?

A: The drawings or samples, quantity, tolerance, standard, material, surface finish, other special requirements, etc.

Q: What're your delivery methods?

A: DHL, EMS, UPS, land transport or sea freight available.

Q: How do you assure the quality control?

A: Full inspection with test report and material composition certificate for each order and 1-year after-sale service for free repair or replacement for deficit products. Almost zero repair rate and defective products all replacement or repair for free.

Q: How long is your lead time?

A: 10-30days up to the quantity.

Q: what surface treatments can you deal with?

A: Titanium nitride (TiN), TiCN, titanium plating, blackening, carburize, zinc plating, zinc coating, galvanization, chrome plate, etc.

Q: what's your payment term?

A: T/T, L/C, western Union, PayPal, etc.

Add.: No.1518, F15, Building 1, Qianhai Life Financial Center, Jinqiao 3rd Road 418#, Chanba Ecological District, Xi’an, Shaanxi, China.